In recent years, although China has basically kept pace with the international level in the research and development of high-efficiency motors, the technological progress is very optimistic; but unfortunately, the domestic application of IE3 motors produced in China is too small, and most of them are used for export. It is not difficult to see that China still has huge challenges in high-efficiency motors.

As we all know, the electricity consumption of electric motors in the industrial sector accounts for about 75% of the total electricity consumption of the industry. Therefore, energy saving of electric motors has become the key to industrial energy conservation. With the dual pressures of energy saving, emission reduction and environmental protection, energy-saving equipment represented by high-efficiency motors has attracted much attention in the market.

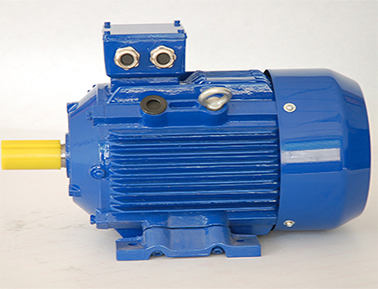

A high-efficiency motor is a motor with a high efficiency of a general-purpose standard motor. High-efficiency motors use new motor designs, new processes and new materials to improve output efficiency by reducing losses in electromagnetic, thermal and mechanical energy. Compared with standard motors, the energy-saving effect of using high-efficiency motors is very obvious, and the efficiency can be increased by 4% on average.

As early as 2008, China has included motor system energy conservation as one of the top ten energy-saving projects in the country. In 2009, it also applied high-efficiency and ultra-efficient motor applications to Huimin Engineering. At the beginning of last year, the National Motor Energy Efficiency Improvement Plan was introduced. The plan mentioned that in 2015, China will upgrade its motor products, and 50% of low-voltage three-phase cage asynchronous motor products and 40% of high-voltage motor products will be highly efficient. The standard of motor energy efficiency standards; the cumulative promotion of high-efficiency motors of 170 million kilowatts, the elimination of 160 million kilowatts of low-efficiency motors, the implementation of motor system energy-saving technology reform of 100 million kilowatts, the implementation of the elimination of motors and efficient remanufacturing of 20 million kilowatts.

In other words, it is estimated that in 2008, energy saving of 80 billion kWh will be achieved, equivalent to saving 26 million tons of standard coal and reducing carbon dioxide emissions by 68 million tons. The Department of Energy Conservation and Comprehensive Utilization of the Ministry of Industry and Information Technology announced that it will officially implement the motor energy efficiency improvement plan nationwide. It plans to use three years to improve the energy efficiency of the national motor and promote the transformation and upgrading of the motor industry, including 30,000 of the annual electricity consumption of 10 million kWh or more. A number of industrial companies will be the focus of implementation of the program. Based on this estimation, the implementation of this plan will drive the demand for high-efficiency motors and related equipment to nearly 100 billion yuan. In the future, with the advancement of the energy efficiency improvement plan, the demand for high-efficiency motors will gradually be released, showing an increasing year by year.

Increased motor energy subsidies have hindered market promotion

Efficient motor promotion dates back to 2008. In 2008, China listed the energy saving of motor system as one of the top ten energy-saving projects in the country. In 2009, it also applied high-efficiency and ultra-efficient motor applications to Huimin Engineering. On June 2, 2010, it issued a notice saying that high-efficiency motors should be included in energy conservation. The scope of implementation of the product Huimin project has made the market promotion of high-efficiency motors attract much attention.

From the perspective of motor power consumption, the motor energy-saving market seems to be popular with energy-saving service companies. Taking Zhongshan as an example, the two largest energy consumptions are boiler (coal consumption) and industrial electricity, while in industrial electricity consumption, motor consumption accounts for more than 70%, including water pump, air compressor, fan, equipment power supply. Systems, etc., such as residual heat, lighting, transportation and other fields account for about 30%.

but it is not the truth. “Many of the business is concentrated on the 30% share, such as waste heat recovery, line transformation, etc.” He Jun, who has been engaged in energy conservation and environmental protection for many years, said that none of the nine professional energy-saving service companies in Zhongshan has specifically promoted the improvement of motor energy efficiency. To do it, only the transformation of the inverter and the servo is included in the entire energy-saving project, and the proportion of the motor business is small.

An energy-saving and environmental protection engineer in Zhongshan said that energy-saving enterprises must intervene in the field of electric motors and need to deploy new electric power engineers. After learning and training and experience accumulation, the effect will probably be reached by the end of the year. The long return on investment may affect the development of energy-saving enterprises. This is also the problem that companies need to face.

However, for energy-saving service companies, the biggest problem is the difficulty in developing the motor market. The main reason is that the price of high-efficiency motors is too high. He Jun said that due to the high technical threshold, the cost of high-efficiency motors is twice as high as that of ordinary motors, and energy-saving funds can only be subsidized by 50%. Others should be supplemented by the electricity saved by improving motor efficiency. "High-efficiency motors can improve motor efficiency by 5%-10%. For enterprises, the energy-saving effect is not obvious, and the attractiveness may not be great." He Jun said with anxiety, "With the policy landing, energy-saving funds are definitely More will be more energy-efficient for motors. Some companies that do other energy-saving projects are even more reluctant to invest, but they are still confused about how to open the motor market. It is difficult to adapt to the moment."

Zhou Sigang, deputy director of the Major Equipment Office of China Machinery Industry Federation, once said to the media that because the cost of high-efficiency motors is increasing, end users have low-cost demands on motors, so it is particularly difficult to promote them.

In addition, there are few manufacturers of high-efficiency motors, which reduces the desire for corporate procurement. During the period from August 2010 to December 2013, the Ministry of Finance and the National Development and Reform Commission distributed the catalogue of high-efficiency motors for “energy-saving products for the benefit of the project”. The latest promotion catalogue consisted of 90 companies, mostly concentrated in Jiangsu, Zhejiang and Shanghai. In the provinces and cities, only three companies including Hepu Power Technology, Dongguan Motor and Jiangmen Jiangyu Motor were selected.

Although the high-efficiency motor subsidy funds continue to increase, but its promotion has been blocked for several years, this is where He Jun and other energy-saving people are more worried. He Jun said that he will contact the relevant motor companies as soon as possible, hoping to find a way to open the market. "In the short run, enterprises may choose to upgrade the motor system first, and the energy efficiency improvement is more obvious. However, in the long run, it is necessary to replace the high-efficiency motor." He Jun predicted, "Now I hope that the high-efficiency motor price can be reduced if the energy-saving subsidy And the power saved after the energy efficiency improvement can make up for the purchase price that needs to be added to replace the motor, then the motor transformation business is easily accepted by the customer."

Browse similar products